Dynamic Seats: Advancing Safety and Comfort in Aircraft Interiors

The Expertise of Generation Global

Generation Global brings significant experience and expertise in the development and certification of seat covers and cushions that comply with the 2X.562 dynamic seat requirements. This advancement has revolutionized the way seats are tested and certified, ensuring that aircraft seating systems not only provide comfort but also play a critical role in occupant safety.

What Are Dynamic Seats?

Dynamic seats are designed to meet strict FAA regulations under FAR 2X.562, which introduced dynamic seat testing in the 1990s. The key difference between dynamic and static seat tests is that dynamic seats are tested as an entire system. This includes not just the seat itself but also:

-

Seat structure

-

Seat track fittings

-

Energy absorbers

-

Stroking mechanisms

-

Restraints and anchors

-

Cushions and upholstery

The dynamic seat system aims to ensure that the seat, along with its components, can handle crash forces and protect the occupant in the event of an accident.

Testing and Certification

Prior to the amendments in the FAA FAR 2X.562 rule, seat testing primarily involved static tests, which did not simulate the forces that might occur during a crash. However, as the need for more robust safety measures grew, dynamic seat testing was introduced. This testing ensures that seats can absorb the forces generated during accidents, particularly those involving energy-absorbing seats. The change in regulations reflected a shift toward improving occupant safety by requiring seats to perform under dynamic conditions.

Previously, the TSO C39 standard was used for seats meeting static requirements. With the introduction of dynamic testing, the updated standard, TSO C127, sets the Minimum Performance Standards (MPS) for seats that comply with the 2X.562 requirements. Any aircraft designs that are type-certified after these amendments are required to meet these dynamic seat standards, ensuring occupant safety is prioritized.

14G Downward Test: A Critical Safety Measure

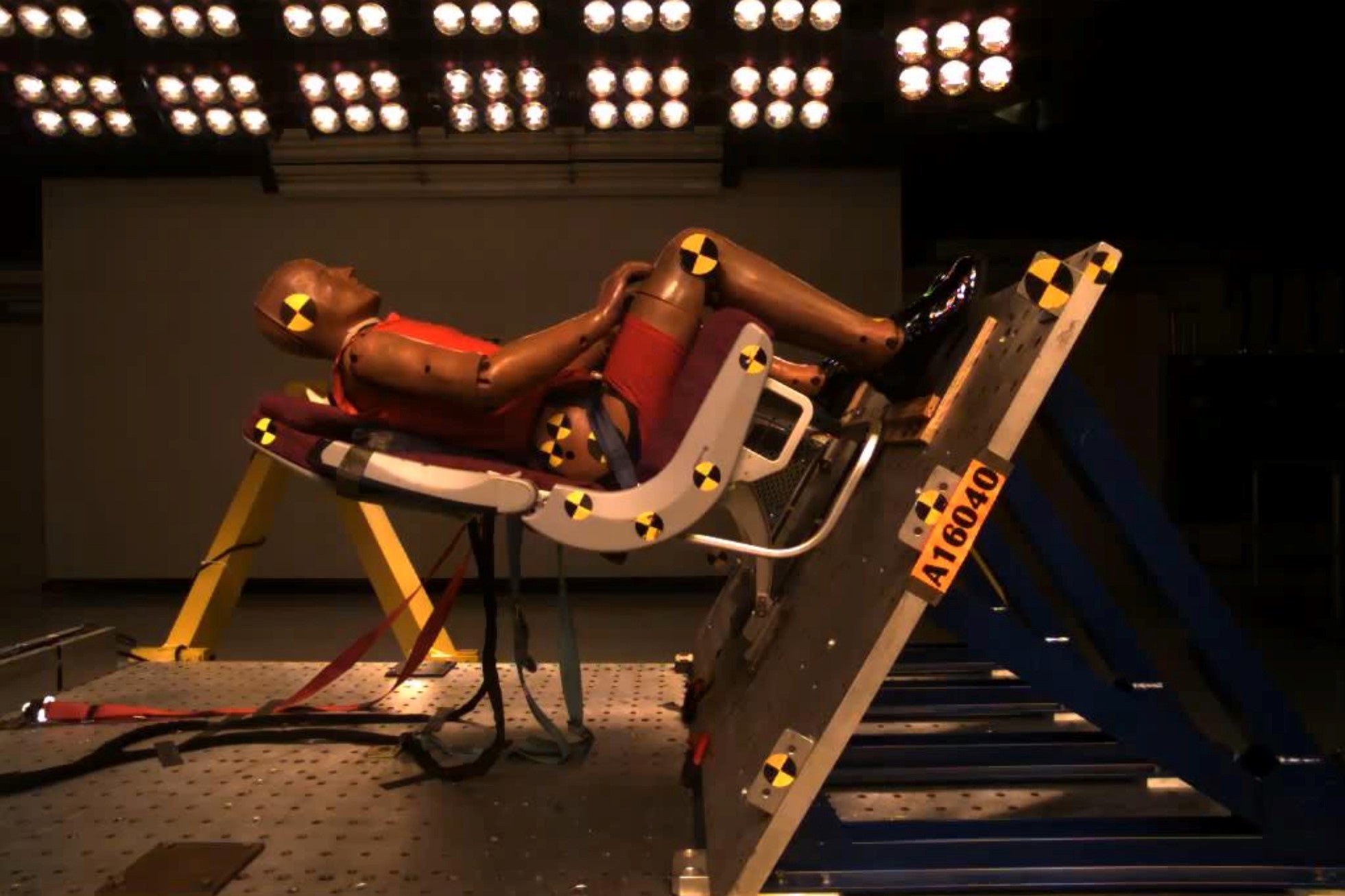

One of the key elements in dynamic seat testing is the 14G downward test. This test is designed to measure the lumber load that an occupant experiences during an impact. According to the 2X.562 requirements, the lumber load should never exceed 1500 lbs.

Watch the video below to see Generation Global conducting a 14G downward test and observe the effect on the occupant's spine. This test simulates a crash scenario to ensure that the dynamic seat and its components can properly absorb and redistribute the forces, reducing the risk of injury.

Why Choose Generation Global for Dynamic Seats?

With decades of expertise, Generation Global is at the forefront of dynamic seat development, ensuring that our seating systems not only comply with the latest FAA regulations but also deliver the utmost in safety and comfort for passengers.

If you're looking to design or refurbish seats that meet 2X.562 dynamic seat standards, Generation Global is your go-to partner. Our team ensures all components are seamlessly integrated, tested, and certified, so you can be confident in the safety of your aircraft's interior.