Enhancing Aircraft Part Traceability with RFID Technology: A Generation Global Innovation

The Project

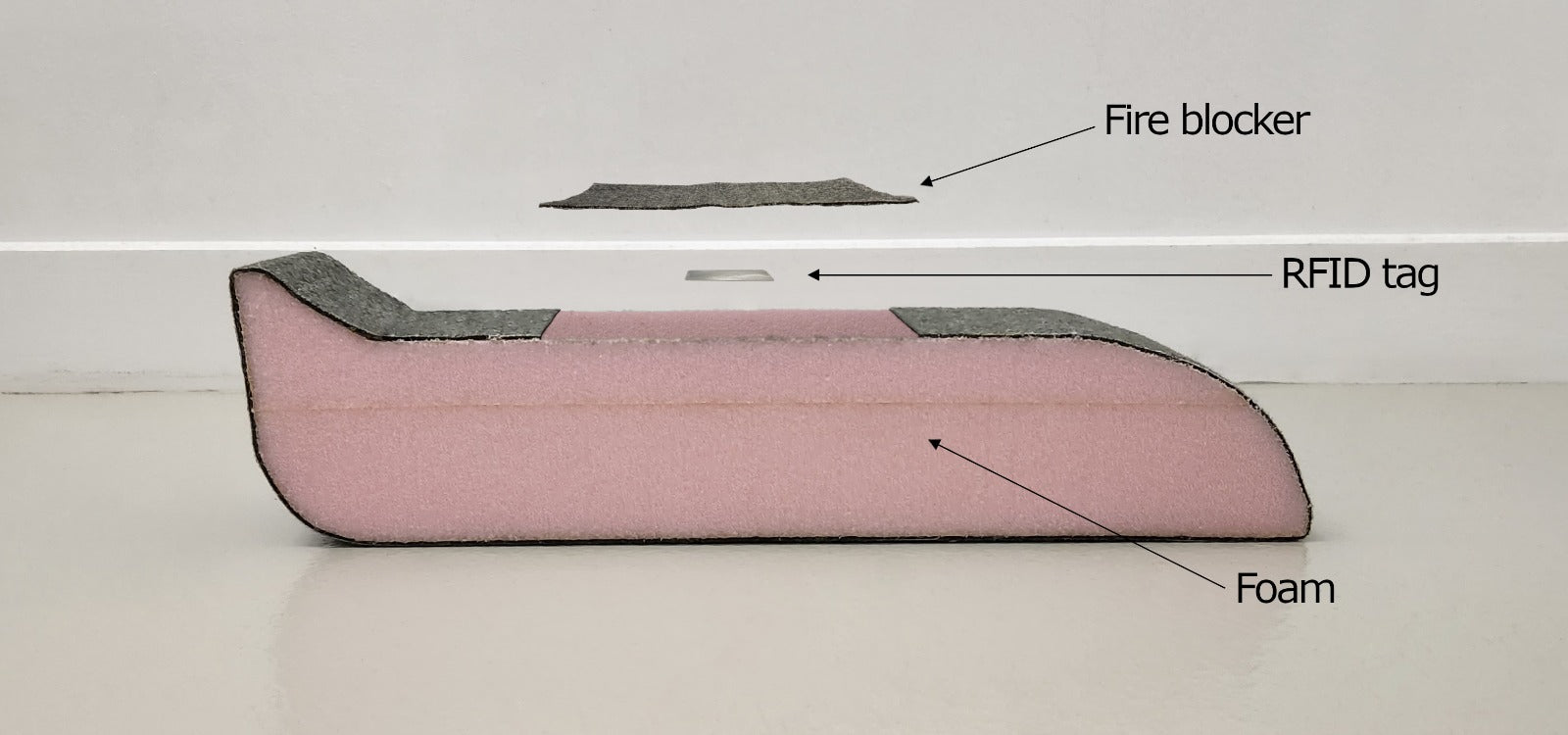

In a recent aircraft seat cushion replacement program, Generation Global partnered with a leading U.S.-based regional airline to integrate RFID tags into seat cushions. This initiative was designed to improve inventory tracking, part traceability, and maintenance efficiency across the airline’s large fleet of regional jets.

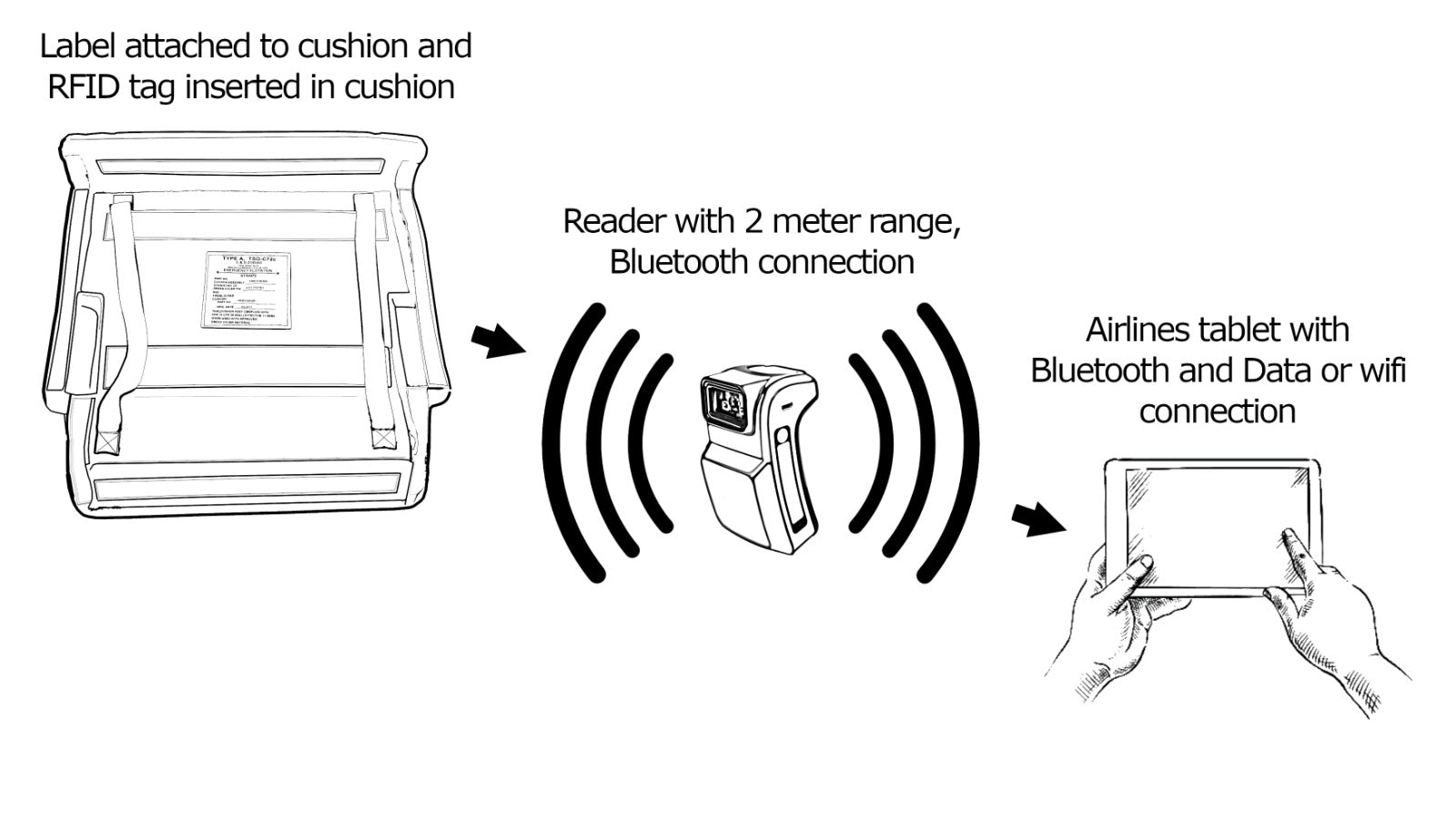

Generation Global delivered a complete solution—providing the RFID-enabled cushions, the technology package, and RFID readers. The result? A smart, streamlined process for tracking and managing aircraft seat cushions across multiple maintenance hubs and aircraft types.

What is RFID?

RFID (Radio-Frequency Identification) is a technology that uses electromagnetic fields to automatically identify and track tags embedded in objects. The system consists of three components:

-

A radio transponder (tag),

-

A radio receiver, and

-

A transmitter.

In this case, the RFID transponder is embedded within the aircraft seat cushion, emitting a unique signal when activated by a transmitter. This signal can be read by a receiver to access important part information—without removing the cushion from the aircraft.

This technology has been used in commercial applications since the 1970s and is now commonly found in passports, hotel key cards, toll systems, and contactless payments.

Why RFID for Aircraft Seat Cushions?

One of the greatest challenges in aircraft maintenance is maintaining accurate traceability of parts—especially soft furnishings like seat cushions, which are regularly swapped during maintenance cycles.

Traditional labels and barcodes can wear off or become detached, but RFID tags remain permanently embedded, providing lifetime traceability of each part.

When an aircraft comes in for scheduled maintenance, engineers can instantly access key data—without removing a single cushion—saving time, reducing errors, and improving compliance with aviation regulations.

RFID Tag Specifications

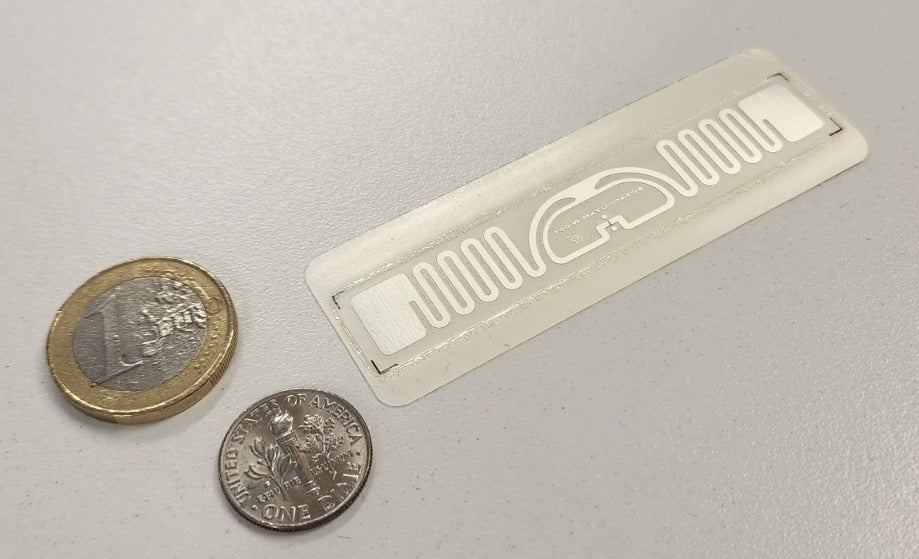

Generation Global’s RFID tags are fully compliant with Aerospace & Defense EPC and ATA Spec 2000 standards. Features include:

-

Dual-record user memory

-

448 bits EPC + 2048 bits user memory

-

Compatible with aviation-standard software

Each RFID tag securely stores essential information such as:

-

Manufacturer

-

Part number

-

Date of manufacture

-

Expiration date

-

Serial number

-

Link to cushion’s burn test certification

This ensures that all required data is accessible at any point during the cushion’s lifecycle—no matter how many aircraft it has been fitted to.

The Client

Our client operates a large fleet of regional aircraft across the United States, servicing multiple airline contracts. With nine maintenance facilities nationwide, traceability, consistency, and inventory control are critical to their operations.

Thanks to this RFID integration, the airline has improved:

-

Efficiency during inspections

-

Accuracy of inventory records

-

Compliance with aviation safety standards

-

Overall maintenance planning and turnaround time

Smarter Aviation Interiors Start Here

At Generation Global, we don’t just manufacture aircraft interiors—we innovate them. From seat cushion upgrades to digital traceability solutions, we help airlines elevate their cabin performance while meeting stringent regulatory and operational requirements.

Interested in RFID integration for your fleet?

Contact Generation Global today to explore custom solutions for your aircraft interiors.